What Are Foundation Walls? Key Construction Insights

Maintaining the structure and integrity of your foundation is a crucial aspect for any commercial property. Not only does this support your building’s living spaces, but it also prevents wall cracks, water penetration, and other long-term, costly structural issues.

In addition to this, Southern California’s climate and seismic activity present a unique set of challenges. Without proper protection and strength, the building can experience structural shifting, uneven walls, or even damage from hydrostatic pressure.

Today’s post serves as a comprehensive guide to foundation walls. We will discuss what they are, their purpose, and the best practices for construction and maintenance. Whether you’re managing an office building or an industrial space, understanding the foundation is essential for long-term stability.

For specific questions about foundation walls, contact the experts at

TMC

Engineering! For those located in Southern California, we can assist and educate on both design and construction that require professional input. Let us help protect your investment with expert guidance and quality construction.

What Are Foundation Walls? Key Construction Insights

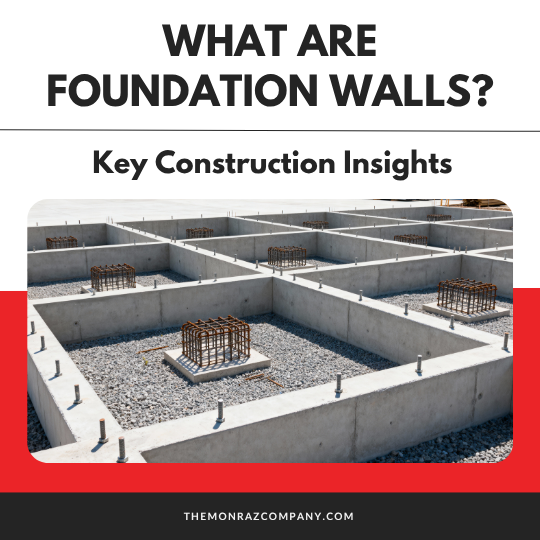

Foundation walls are structural components that transfer a building’s weight to the concrete footings and soil below. Essentially, this reduces the pressure from the building’s walls and floors that would otherwise lead to cracking, bowing, and settling.

In general, foundation walls are used to support basement walls, create crawl spaces, or provide perimeter support for slab-on-grade buildings. Additionally, they protect the building’s integrity from moisture perforation, soil movement, and natural erosion.

In commercial construction, foundation walls are more than support—they’re part of a critical system designed for long-term durability. Moreover, regular inspections are essential to prevent costly foundation wall repairs later on.

What Are Foundation Walls Made Of?

Foundation walls can be constructed from a variety of materials depending on the property manager or business owner’s unique needs. Materials also depend on factors such as soil type, climate, budget, and building design. However, common materials include:

- Poured Concrete: Strong and durable, resistant to soil pressure, joint-free, and provides a longer lifespan

- Reinforcing Bars: Enhance concrete’s tensile strength, can withstand heavy loads, and are necessary to meet building code requirements

- Concrete Masonry Units (CMUs): Can handle heavy loads, are cost-effective, not susceptible to pests and rodents, and provide resistance to fire, rot, and water damage

- Drainage Systems: Used to prevent water buildup that causes structural damage, generally combined with gravel, geotextile fabric, proper grading, and barriers

- Wall Anchors: Generally used in repairs rather than new builds to straighten foundation walls under pressure from surrounding soil

- Insulation: Increasingly popular, insulated foundations assist in both comfort and energy efficiency

What is the Best Material for Foundation Walls?

Poured concrete provides superior strength and longevity, making it the best choice for foundation walls. A poured concrete foundation wall is one continuous, joint-free wall. This allows it to support heavy structural loads while resisting shifting, soil pressure, and water penetration.

Additionally, poured concrete foundation is also extremely flexible. It can be quickly constructed in any shape, thickness, or height. The durability and customization opportunities combined make this the wisest choice for most commercial and industrial property owners.

What Is the Purpose of Foundation Walls?

Support the Structure Above

Foundations are the primary building element that supports a property’s structural integrity. It carries the combined load of all the floors, framing, interior walls, and roof, distributing the weight evenly.

Most importantly, foundation walls transfer this weight down to the concrete footings within the soil. This is vital, as the foundation bears the weight of both vertical and horizontal forces. Additionally, foundation walls allow for seamless modifications and future expansions if necessary.

Resist Soil Pressure

Built with stability in mind, foundation walls withstand both lateral and hydrostatic forces, resisting the constant pressure exerted by the soil. However, although concrete is highly durable while under compression, circumstances change when dealing with tension and lateral forces.

Proper reinforcements ensure that buildings do not experience cracking, bowing, or a complete collapse. More specifically, the foundation wall is further supported by the concrete footing, drainage systems, reinforcing bars, and, in some cases, wall anchors.

Prevent Water Penetration

Foundation walls play a crucial role in keeping water out of the building, working alongside proper drainage systems and basement waterproofing to protect against leaks and flooding. However, this function extends to both interior and exterior surfaces.

Internally, professionals will apply plastic sheeting or insulation to prevent moisture from condensing on walls and interior spaces. In addition to this, drainage systems utilize pipes to direct water outside the structure. Externally, however, waterproof coating (such as asphalt emulsion or rubber membranes) is applied to create an impermeable barrier.

Both interior and exterior mechanisms are essential for preventing water from resulting in costly repairs.

Anchor the Building Against Movement

As we mentioned previously, modern foundation walls are constructed to transfer pressure from the wall to concrete footings. By using anchors, this ensures the wall remains stable and the structure is securely supported.

The more a building is affected by poor soil conditions or seismic activity, both of which are prevalent in Southern California, the greater the risk of serious structural damage. In turn, this puts property managers, building owners, and occupants in danger. Proper design is crucial in mitigating hazards and protecting investments in commercial properties.

Provide Insulation and Energy Efficiency

While less common in older buildings, insulated foundation walls offer significant advantages for commercial properties. They help regulate temperatures in basements and lower-level spaces, improving comfort and protecting stored material.

As a result, the temperature regulation also enhances energy efficiency, creating a thermal barrier that reduces heat transfer between the building and the surrounding soil. Construction companies typically apply insulation in two ways: exterior insulation before backfilling, followed by interior insulation once the wall is in place.

How Thick Are Foundation Walls?

The thickness of a foundation wall will depend on the building type, soil conditions, wall height, and wall material. However, here are the general guidelines based on commonly used materials:

- Poured Concrete Walls: In commercial construction, poured concrete walls range from 8 to 12 inches in thickness. However, they can be up to 10 to 12 inches for exterior or load-bearing walls.

- Concrete Block Walls: For commercial buildings, concrete block walls are typically 8 to 10 inches thick. However, for high-rise buildings, warehouses, or factories, walls are often constructed 12 inches thick to meet structural demands.

As we mentioned previously, however, regulations are entirely dependent upon external factors. In areas with poor soil, seismic activity, or high water tables, thicker foundation walls are necessary to ensure structural stability.

Additionally, California building codes specify minimum requirements for materials, reinforcements, and wall thickness. To learn more, review the

California Building Code, Title 24,

Part 2 (Volumes 1 & 2).

How to Build a Foundation Wall Out of Poured Concrete

Hire a trusted contractor.

For long-term stability, it’s essential to hire trusted contractors who understand both the design requirements and professional construction standards. At TMCEngineering, we deliver precise construction, reinforcement, and maintenance services that meet the unique demands of each structure.

Additionally, a reputable team should have expert-backed knowledge about Southern California’s unique soil and seismic activity. With the proper tools and expertise, you can trust that professionals will complete the job correctly the

first

time.

To learn more, read our post: “Tools for Concrete: Essential Equipment for Concrete Projects.”

Excavate the site.

For proper installation, it’s crucial to excavate the site. This ensures the area is free of debris and unstable topsoil, and, in colder temperatures, helps prevent frost heaving. With a clear base, professionals can successfully install underground utilities and prevent future structural damage.

Most importantly, however, this is crucial for California code compliance, as discussed in

CBC Section 1804. Additionally, to learn more about foundation wall installation in cold temperatures, visit “When Can You Pour Concrete?”

Install the footings.

To install footings for a foundation wall, you must first excavate the trench. Ensure that this is to the correct depth, as improper measurements can lead to structural instability and uneven settlement.

Additionally, it should be wide enough for both the footing and the formwork. Make sure that the soil is both level and compact, creating a stable foundation for the structure. Finally, add a layer of either compacted gravel or crushed stone

prior

to placing the wall forms.

Once the footing has cured, contractors can safely begin setting the vertical reinforcing steel and constructing the wall forms on top. This ensures the wall is tied structurally into the foundation below.

Set up the wall forms.

Now, it’s time to build the wall forms. These act as stencils for the poured concrete. Contractors assemble this temporary structure to contain the wet mix until it cures fully. These forms are typically made from plywood, metal panels, or other engineered form systems designed for strength and precise alignment.

Once the forms are in place, they’re braced with strongbacks, whalers, and diagonal supports to keep everything stable. Spreaders and form ties help maintain the correct wall thickness and prevent movement or concrete blowouts during the pour.

Before placing concrete, contractors apply areleaseagent to the inside of the forms. The coating creates a thin barrier that stops the concrete from bonding to the framework. This ensures the forms can be removed cleanly and the finished wall surface remains smooth and uniform.

Place the reinforcing steel.

To keep the concrete strong under compression, contractors install steel reinforcement (rebar) inside the wall forms. The rebar provides the tension strength that concrete lacks on its own. This supports the foundation, so it does not bend, shift, or buckle under structural stress.

By tying the steel into a continuous grid, the wall becomes increasingly better suited to handle soil movement, settling, and even seismic forces. This reinforcement greatly reduces the risk of cracking and helps the foundation perform reliably over its entire lifespan.

Pour the concrete.

Finally, the foundation is ready to be poured. Contractors will use concrete pumps or chutes and pour concrete into the forms evenly. They work in controlled lifts, filling the forms a few feet at a time to manage pressure and prevent blowouts.

As contractors place the concrete, they use internal vibrators to consolidate each layer, removing trapped air and ensuring a dense, uniform wall. The crew moves along the form system until the entire wall reaches the specified height. The result is a solid, continuous pour without cold joints.

Screed and finish the top.

After contractors pour the concrete, they level the top of the wall with a screed board or finishing tool. They create a clean, uniform surface that supports future installations like sill plates, framing connections, and waterproofing membranes. A smooth top also helps the wall shed water and reduces the chance of surface defects later.

While the concrete remains workable, crews set the anchor bolts, hold-downs, and other embedded hardware. They position each piece precisely so it lines up with the future framing layout. Proper placement at this stage locks the structure to the foundation, improves load transfer, and strengthens the building against uplift, shear, and lateral movement.

Allow the wall to cure.

Once contractors pour the concrete, it must cure properly to reach its intended strength and durability. Curing is the controlled process of retaining moisture and regulating temperature, allowing the concrete to hydrate fully.

To support this process, contractors use several methods. They may leave the forms in place to protect the fresh concrete or apply curing compounds that retain moisture. If it’s cold, they may also cover the wall with insulated blankets. If needed, here’s more essential information on

pouring cement in cold weather.

In hot or dry weather, they might lightly mist the surface or wrap it to slow evaporation and prevent early-age cracking.

This careful moisture and temperature management continues for several days. The process confirms the wall develops adequate strength, resists long-term cracking, and performs as a stable structural element.

Remove the forms.

After the concrete has cured to the required strength, contractors carefully strip away the forms without damaging the new wall. This process involves removing bracing, disconnecting form ties, and dismantling panels in a controlled sequence to prevent chipping or stress on the concrete.

Once exposed, the wall is thoroughly inspected for issues such as

honeycombing, voids, surface cracks, or misalignment. Contractors will then go in and repair any imperfections using approved patching materials or grout, restoring uniformity and structural integrity.

Apply waterproofing and drainage systems.

To protect the foundation wall from moisture intrusion, contractors will install waterproofing membranes, coatings, drainage mats, or protective boards.

Additionally,

perforated drainpipes (Frenchdrains) are placed along the exterior footing to direct water away from the structure. These systems reduce hydrostatic pressure and help prevent long-term water-related damage.

Backfill gradually.

The final step is backfilling around the foundation. Contractors must do this gradually and with the right type of soil (typically a well-draining material). Then, they will compact the soil in layers to avoid excessive pressure or uneven settling against the foundation wall.

Backfilling should only begin once the structure above provides adequate lateral support, preventing wall movement or bowing.

All well-constructed buildings start with a solid foundation.

Foundation walls do more than simply hold up a building. They protect your structure from soil pressure, moisture intrusion, earthquakes, and long-term structural fatigue. When built and maintained correctly, they provide the strength, stability, and durability every commercial property needs to perform safely for decades.

If you manage or own property in Southern California, partnering with experts who understand the region’s soil conditions, seismic demands, and building code requirements is essential. TMC Engineering specializes in designing, constructing, and maintaining poured concrete foundation walls built for long-term performance.

Whether you need new construction, reinforcement, or structural repair, our team delivers precision workmanship and reliable, code-compliant solutions.

Contact TMC Engineering today to protect your investment and ensure your foundation stands strong for years to come.