How Do You Cut Cement Board? Best Tools and Techniques

Cement board is one of the most commonly used concrete-based products in both commercial and residential construction. It’s valued primarily for its durability, performance, and moisture-resistant properties. Even in demanding environments, cement board remains a reliable and supportive material for tile, stone, and other finishes.

All types of cement board are also considered to be generally easy to install. Nonetheless, without the right tools and techniques, even the simplest cement board projects can result in cracked panels, inaccurate cuts, and wasted material.

Therefore, this guide is a comprehensive overview of how to cut cement boards effectively based on different types of cuts, tools available, and working conditions on the site. For commercial and industrial projects, this level of precision and durability are essential for longevity and performance.

At TMC Engineering, our team understands how to properly handle, cut, and install cement boards as part of larger concrete and construction systems. If you’re planning a project in Southern California and need expert guidance or execution,

TMC Engineering is here to help ensure the job is done right the first time.

How Do You Cut Cement Board? Best Tools and Techniques

A proper understanding of this versatile material is crucial for using it effectively. In the sections below, we’ll outline what cement boards are, their most common applications, and the tools best suited for handling and installation.

We’ll also walk through proven techniques for cutting cement boards accurately and safely. In doing this, this knowledge allows contractors to approach projects with confidence to achieve clean, professional results.

Here’s what you need to know:

What Is Cement Board?

Cement board, also known as cement backer board (CBU), is a rigid, durable building panel made from a combination of cement, water, and reinforcing fibers. The primary purpose of cement board is to provide a suitable base for stone, masonry, or tile installations. More specifically, it does so by using a thin-set mortar and additional bonding materials.

It’s a favored building material for floors and walls because it’s fire-, mold-, and water-resistant, unlike drywall or other bases. Contractors often use cement board in kitchens and bathrooms because of the commonly wet conditions. However, there are other interior and exterior applications depending on the project and the manufacturer's instructions.

Note: Though moisture-resistant, cement board is not the same as

waterproof cement.

Commercial and Industrial Uses for Cement Board

- Commercial restrooms

- Locker rooms and shower facilities

- Commercial kitchens and food-prep areas

- Restaurant and hospitality interiors

- High-traffic flooring areas

- Laundry rooms and janitorial closets

- Utility and mechanical rooms

- Fireplaces, hearths, and other areas in need of fire resistance

- Exterior soffits and eaves

- Exterior wall assemblies with tile, stone veneer, or architectural cladding

Can You Cut Cement Board?

Yes, you can cut cement boards. However, it requires the right techniques and tools for concrete projects. This is because it’s both harder and more brittle than drywall. For strength, cement boards contain Portland cement and reinforcing fibers, giving it a dense, rigid structure.

At the same time, because they lack the soft

gypsum core of drywall, cement boards don’t compress or flex as easily. This makes it increasingly difficult to cut. Although it’s highly durable, it offers no flexibility and is often applied in thin layers. As a result, if not handled properly by contractors, it can crack or snap rather than bend.

There are several types of cement boards made from slightly different materials, including:

- Traditional Cement Backer Board (CBU): Made from cement and sand reinforced with fiberglass mesh

- Fiber-Cement Board: Cement combined with cellulose or synthetic fibers

- Glass-Fiber Reinforced Cement Board: Uses glass fibers instead of mesh for added strength and crack resistance properties

- Exterior-Grade Cement Board: Specifically rated for outdoor exposure when properly detailed

What to Cut Cement Board With to Prevent Cracking or Breaking

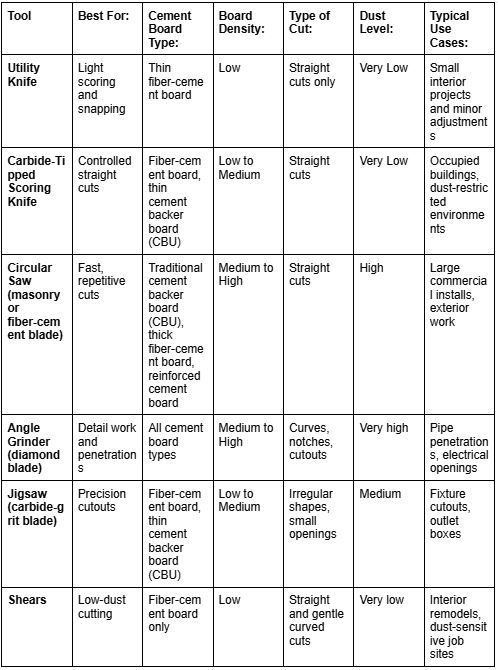

There are a variety of tools for cutting cement boards. Because they each have a specific function, are only suitable for a certain density, and can stir up a lot of dust, the cutting tool you use is essential to the success of your project.

How to Cut Cement Board

For Straight Cuts: Score and Snap

- Step One: Measure and mark your cut line.

- Step Two: Score the board along the line. Use a utility knife or carbide scoring tool.

- Step Three: Flip the board and snap it downward along the score.

- Step Four: Cut through the mesh backing if needed.

For Straight Cuts: Cement Board Shears

- Step One: Measure and mark your cut line clearly on the cement board.

- Step Two: Use manual or electric cement board shears. Ensure they are rated for fiber-cement material.

- Step Three: Cut steadily along the marked line, allowing the shears to do the work.

For Small or Detailed Cuts: Jigsaw

- Step One: Measure and mark the detailed cut line clearly on the cement board. For best results, trace the outline using the fixture, box, or a template for accuracy.

- Step Two: Attach a carbide-grit blade to the jigsaw.

- Step Three: Cut at a slow, steady speed to reduce blade wear and minimize chipping.

For Long Cuts: Circular Saw

- Step One: Measure and mark your cut line clearly using a straightedge.

- Step Two: Move the cement board to an outdoor or well-ventilated area. This will reduce silica dust exposure.

- Step Three: Fit a masonry or fiber-cement blade onto the circular saw.

- Step Four: Cut slowly and steadily, keeping the saw aligned with the marked line to prevent binding, chipping, or excessive blade wear.

For Notches and Curves: Angle Grinder

- Step One: Measure and mark the cut area clearly on the cement board. For curved cuts, trace the outline using the fixture itself or a template to ensure accuracy.

- Step Two: Attach a diamond blade to your angle grinder.

- Step Three: Make shallow passes along the marked line instead of forcing the cut.

Cut cement board utilizing these expert techniques.

Cutting cement boards correctly comes down to using the right tools and techniques for the job. Taking the time to plan each cut and match the tool to the material ensures more efficient installation and long-term performance. More importantly, clean cuts protect the material, improve installation quality, and help prevent costly mistakes.

If you’re planning a cement board installation as part of a larger construction project, contact

TMC Engineering. Our team offers the experience and technical knowledge needed to deliver consistent, high-quality results. Additionally, we support projects across Southern California—from planning through execution.

For next steps on common cement board-dependent projects, read these posts next: