Cold Pour Asphalt Crack Filler: Uses, Benefits, and Limitations

Property owners and contractors consistently choose asphalt for many reasons. It’s affordable, quick to install, recyclable, durable, and easy to maintain. However, while asphalt delivers long-term performance and allows for straightforward repairs, cracks will inevitably form over time.

This is especially true in parking lots and high-traffic areas. Although freeze-thaw cycles are commonly responsible for asphalt cracking, there are several other contributing factors. Water infiltration, oxidation, heavy traffic loads, ground movement, and poor installation practices may also contribute to pavement failure.

Fortunately, these cracks are often easy to fix—but timely crack filling and repair is essential to prevent water from entering the pavement and causing more damage. Therefore, in this post, we will discuss why cold-pour asphalt crack filler offers a simple, fast, and cost-effective solution.

For expert asphalt repair in Southern California,

contact TMC Engineering. Our team restores cracked asphalt and other types of surface damage using proven methods that extend pavement life and support long-term performance.

What Is Cold Pour Asphalt Crack Filler?

Cold pour asphalt crack filler is a ready-to-use sealing material used to fill and seal cracks in asphalt pavement. Contractors and property owners appreciate cold-pour concrete because it does not require heating like hot rubber crack filler. It also doesn’t require specialized equipment, large budgets, expansive crews, or prolonged service disruption.

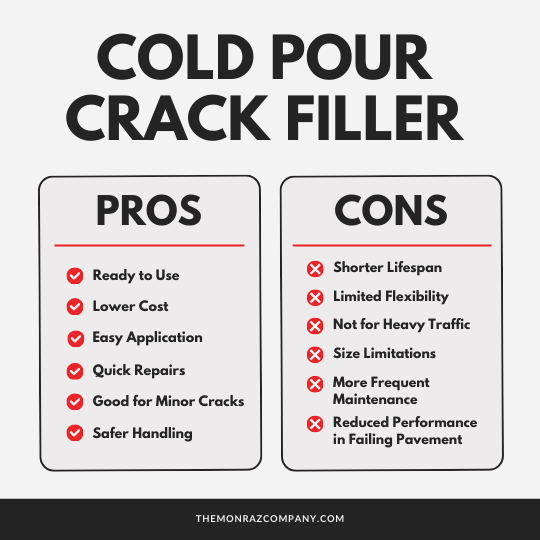

Below, we will offer a more comprehensive look at the pros and cons of cold-pour crack filler in commercial construction.

Dealing with a pothole? Follow our

asphalt cold patch guide instead.

Pros and Cons of Cold Pour Crack Fille

Pros

- Ready to Use: Cold pour crack filler comes pre-mixed and can be applied directly from the container without heating.

- Lower Cost: It eliminates the need for specialized equipment, making it a more affordable option for small-scale repairs.

- Easy Application: The material is simple to apply and suitable for property staff, maintenance crews, or DIY use.

- Quick Repairs: Cold-pour products allow for fast application and minimal disruption to traffic or operations.

- Good for Minor Cracks: It performs best on narrow, non-working cracks with minimal pavement movement.

- Safer Handling: Because no heating is required, there is a lower risk of burns or jobsite safety hazards.

Cons

- Shorter Lifespan: Cold pour crack filler typically does not last as long as hot pour sealants.

- Limited Flexibility: The material is less able to expand and contract with temperature-related pavement movement.

- Not for Heavy Traffic: It may wear prematurely in high-traffic or load-bearing areas.

- Size Limitations: Cold pour products are generally recommended only for cracks up to about one inch wide.

- More Frequent Maintenance: Repairs often need to be monitored and reapplied more often over time.

- Reduced Performance in Failing Pavement: Cold pour filler is ineffective when cracks result from base or structural issues.

What Is Cold Pour Crack Filler Made Of?

Cold pour crack filler is made from a blend of asphalt-based binders and performance additives specifically designed to seal pavement cracks without heating. The primary component is asphalt or bitumen, which allows the material to adhere to the crack walls and form a watertight seal.

Manufacturers also add rubber or polymer modifiers to improve flexibility. This helps the filler accommodate minor pavement movement without cracking or pulling away. Additionally, to keep the material pourable at various temperatures, cold-pour crack fillers include solvents or carrier agents that evaporate or cure after application.

Equally important, adhesion promoters in crack filler improve bonding to clean asphalt surfaces. Then, stabilizers and fillers enhance durability and resistance to weathering. With all these ingredients combined, cold pour crack filler leaves behind a flexible, asphalt-based seal that helps block moisture intrusion and slow further pavement deterioration.

Types of Asphalt Filler

“Hot” or “cold” pour asphalt filler only refers to the two application methods. However, several types of asphalt crack filler can be applied hot or cold depending on the manufacturer’s instructions, the crack conditions, and the performance requirements of the repair.

Here are the types of asphalt filler:

- Cold Pour Crack Filler: Ready to use without heating and best for small, non-moving cracks

- Hot Pour Crack Sealant: Heated before application and ideal for active cracks and heavy-traffic areas

- Rubberized Crack Filler: Contains rubber additives to improve flexibility and accommodate pavement movement; available in hot or cold formulations

- Polymer-Modified Crack Filler: Uses polymers to enhance adhesion, elasticity, and durability; can be applied hot or cold

- Emulsion-Based Crack Filler: Water-based and cold-applied only; easy to apply but typically shorter-lasting

- Mastic or Banding Sealers: Thick, high-build materials typically applied hot to reinforce wide or deteriorated cracks; some cold-applied versions are available

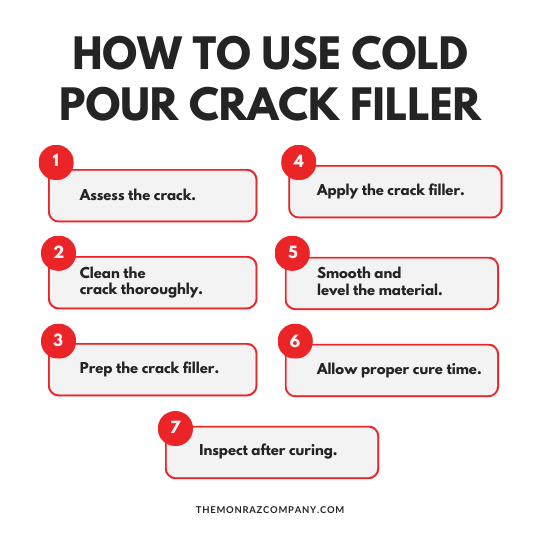

How to Use Cold Pour Crack Filler

Step One: Assess the crack.

Before you use cold-pour crack filler, confirm it’s the right product for the crack you plan to repair. Cold pour crack filler works best on narrow to moderate cracks. Wider cracks with missing asphalt or crumbling edges require a more extensive repair method.

When you assess the crack, check that the surrounding pavement is not soft, sinking, or

showing alligator cracking. These conditions indicate structural failure below the surface, which a crack filler cannot fix. Finally, look for moisture inside the crack. If you see mud or dampness, dry the crack completely before moving forward.

Step Two: Clean the crack thoroughly.

Next, clean the crack. Crews often rush this step, but inadequate preparation can compromise the entire repair. Use the following steps to properly clean and prepare the area:

- Use a wire brush, flathead screwdriver, or specialized crack-cleaning tool to loosen dirt, gravel, weeds, and deteriorated asphalt in and around the crack. Sweep away the loose material.

- Use a leaf blower or air compressor to remove remaining dust and fine particles.

- Pull out any roots or organic material left in the crack after the initial cleaning.

- Check again for moisture. If moisture remains, allow the crack to dry fully before proceeding.

Step Three: Prep the crack filler.

To determine how much product you need, measure the total linear feet of cracks. Then, cross-reference that measurement with the coverage rate (linear feet per gallon) listed on the product you plan to use.

Fortunately, most cold pour crack fillers are easy to use. However, read the manufacturer’s instructions before you begin. Some products require shaking or mixing, while others allow you to pour directly from the container.

The product instructions also specify which application tools to use, such as a pour spout, a caulking gun, a squeegee, or a trowel. Gather these asphalt tools before you open the container. Because crack filler sticks to skin and clothing, wear gloves and designated work clothes before you start.

Step Four: Apply the crack filler.

When the weather stays dry and temperatures reach approximately 40°F or higher, apply the crack filler. Start slowly and pour or dispense the filler gradually into the crack to avoid overfilling. As you pour, move the container or application tool steadily along the crack so the material fills evenly without gaps or air pockets.

Step Five: Smooth and level the material.

Once you fill the crack, smooth and level the material immediately. Doing it right away ensures the filler remains workable while you shape it. Moreover, use a squeegee or putty knife to level the surface and feather the material slightly past the crack edges.

Doing so ensures water doesn’t collect at the seam. After you’ve smoothed the filler, press it firmly into the crack edges to improve adhesion and long-term performance.

Step Six: Allow proper cure time.

Follow the manufacturer’s instructions for cure time. Cure times vary based on temperature, humidity, crack depth, and filler type. Some products set within minutes, while others require several hours.

Additionally, while the filler is curing, keep vehicles and foot traffic off the repaired area. If weather conditions turn before curing finishes, cover the repair to prevent washout or adhesion issues.

To learn more about ideal conditions for asphalt repair, visit our guide: “Can You Pour Concrete in Cold Weather?”

Step Seven: Inspect after curing.

After the filler cures, inspect the crack again. The material should bond fully to the crack edges without peeling or separation. During this inspection, also check for settling or shrinkage. If you find significant voids, consider applying a second layer of asphalt filler.

Cold pour asphalt crack filler is a smart choice for regular asphalt maintenance.

Cold pour asphalt crack filler is a practical solution for routine pavement maintenance when used in the right conditions. It helps seal out moisture, slow crack growth, and extend the service life of asphalt surfaces when applied correctly and monitored over time. Ultimately, using cold pour in the right situations (and choosing advanced repairs options when needed) helps protect your pavement investment.

For professional asphalt crack repair and long-term pavement solutions in Southern California,

contact TMC Engineering. Our team evaluates pavement conditions, selects the proper repair methods, and delivers durable results designed to support traffic demands and extend pavement performance.