Managing Asphalt Cement Bucket Waste: A Detailed Guide

Construction waste management isn't just about keeping job sites clean, it's about avoiding headaches that can shut down your operation. And, when you’re dealing with complex and potentially hazardous materials like asphalt cement, learning proper waste management techniques are crucial. Even something as seemingly minor as a bucket of waste can lead to environmental violations, hefty fines, and tricky legal complications.

On a commercial site, professionalism and efficiency are key. Mastering cleanup procedures isn’t

just

good practice it’s a critical component of a successful job. Today, we're walking through a practical guide for managing asphalt cement bucket waste that meets the demand of real-world commercial job sites.

If you’d like a quicker or more specific answer to your asphalt or concrete repair questions, call the experts at

TMC Engineering! If you’re in Southern California, we can help educate you on your problem and perform whatever repair is necessary. We’ve got an expert solution for your commercial concrete or asphalt concerns!

Managing Asphalt Cement Bucket Waste: A Detailed Guide

This guide offers a comprehensive overview of how to properly manage asphalt cement waste to help you avoid surprise costs and regulatory trouble. You'll discover proven strategies that commercial property managers rely on to stay compliant and control project costs. We've packed this guide with actionable advice based on what happens on real-world job sites, not just theories from textbooks.

Commercial construction generates

tons of asphalt cement waste. Every paving, parking lot repair, and roadway job creates buckets of leftover material that requires proper disposal and management. But, the challenge isn't just disposal; it's doing it right the first time so you don't face bigger problems later.

The reality is harsh: environmental violations stick with your business for years. They show up in background checks, affect bonding capacity, and make insurance companies nervous. Well-informed property managers get ahead of waste issues before they become expensive problems.

What Is Asphalt Cement?

Asphalt cement is essentially the binding agent in asphalt concrete mixtures. It's a thick, black, viscous substance that comes from refining crude oil. More specifically, it comes from the heavy hydrocarbon compounds left over after making gasoline and diesel fuel. Without asphalt cement, those stones and sand in your pavement would just be a pile of loose rocks.

This material also behaves differently depending on temperature.Heat turns asphalt into a workable liquid, whereas cooling it makes it harden into a durable surface. That's why timing matters so much during installation especially in the hot California sun. If the temperature is wrong, you've got unusable waste on your hands.

Modern asphalt cement includes recycled content, performance boosters, and special additives that make roads last longer. And while these additives are improvements, they also make waste management more complex; you're not just dealing with plain asphalt anymore!

Ongoing environmental concerns related to asphalt cement have prompted a rise in regulatory oversight.

Polycyclic aromatic hydrocarbons (PAHs) and other compounds can contaminate soil and groundwater if handled improperly. What does this mean for your company? One spill in the wrong place and you're looking at expensive cleanup costs that could have been avoided.

Storage mistakes create the most waste. Let asphalt cement get too cold, and it becomes unusable chunks. Let it overheat, and the chemistry changes enough to ruin entire batches. Commercial properties that nail their storage procedures cut waste by 40% or more compared to those that wing it. This is why it’s critical to learn the proper way to manage asphalt cement! You can cut costs, improve reputation, and eliminate unnecessary waste at the same time.

How Is Asphalt Cement Made?

The production process starts with crude oil distillation, where it’s heated and separated by boiling points into different components. Lighter products like gasoline and diesel are removed first. The heavier leftover material serves as the base for asphalt cement.

Additional processing operations are used to meet specific performance requirements, like air blowing. Air blowing involves passing hot air up to 500°F through liquid asphalt. This process oxidizes and hardens

it asphalt, improving its heat resistance, durability, and workability.

In terms of factory waste, it can vary widely based on refining operations and quality control procedures. Most manufacturing facilities generate 2-5% waste material that has to be disposed of properly. Examples of this include off-spec lots, equipment-cleaning residues, and spoiled materials that are no longer suitable for sale.

Quality testing also produces secondary waste streams as samples undergo various performance tests. This testing ensures end-products are specification compliant, but produce small volumes of waste in the long run. Commercial purchasers must consider such waste streams in arranging disposal for their projects.

To help with waste output, manufacturers increasingly incorporate

recycled asphalt pavement (RAP) and

recycled asphalt shingles (RAS) into new products. Although these measures reduce waste production, they complicate waste classification and waste disposal processes. Fly ash filler operations must treat this new material according to regulations for coal combustion byproducts.

Finally, temperature control throughout production significantly affects waste rates. Overheating degrades the asphalt, creating unusable material that requires disposal as hazardous waste. Conversely, insufficient heating prevents proper mixing and quality achievement, resulting in rejected batches that add to waste volumes.

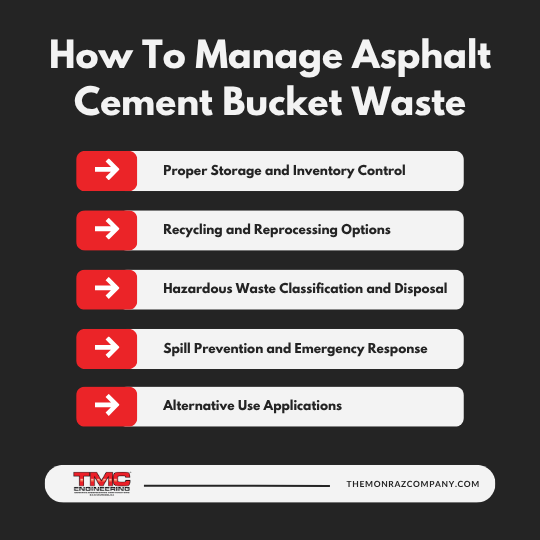

How To Manage Asphalt Cement Bucket Waste

Proper Storage and Inventory Control

Implementing systematic storage procedures minimizes waste generation while maintaining the material’s quality. Store asphalt cement buckets in temperature-controlled environments that prevent excessive cooling or heating cycles. Otherwise, extreme temperature variations can cause material degradation that renders entire containers unusable, creating unnecessary waste streams.

Another method for managing asphalt cement bucket waste is an inventory rotation system. This ensures older materials receive priority before quality degradation occurs. Commercial properties should establish first-in, first-out protocols that prevent materials from exceeding shelf life limitations. Digital tracking systems help monitor inventory ages and schedule usage accordingly.

With inventory control comes properly stacking and handling procedures to prevent container damage that leads to spillage and contamination. Use appropriate lifting equipment and storage racks designed for asphalt cement containers. Damaged containers often require complete disposal as hazardous waste, significantly increasing disposal costs compared to normal handling procedures.

Like we discussed temperature previously, climate control becomes particularly important in regions experiencing extreme temperature variations. Facilities should maintain storage areas within manufacturer-recommended temperature ranges to preserve material workability. Investment in proper storage infrastructure pays dividends through reduced waste generation and improved material performance.

Recycling and Reprocessing Options

Many asphalt cement waste materials can undergo reprocessing to create usable products, ultimately minimizing the amount of waste produced. Work with specialized recycling facilities that accept petroleum-based construction waste for conversion into lower-grade applications. These facilities often process waste asphalt cement into products like driveway sealers, roof coatings, or industrial adhesives.

Cold recycling techniques allow the incorporation of waste asphalt cement into new pavement mixtures. Although this process requires specialized equipment and expertise, it can significantly reduce disposal costs while creating environmentally beneficial outcomes. Commercial projects generating large waste volumes should evaluate cold recycling feasibility during the planning phases.

Some waste streams can be reprocessed on-site using portable heating and mixing equipment. This approach works particularly well for projects generating substantial quantities of similar waste materials. However, on-site reprocessing requires proper permits and air quality monitoring to ensure regulatory compliance.

Partnership with asphalt production facilities may provide disposal alternatives for compatible waste materials. Many producers accept clean asphalt cement waste for incorporation into new products, though transportation costs and minimum quantity requirements may limit feasibility for smaller projects.

Recycling options turn waste into valuable resources, making projects more sustainable, cost-effective, and environmentally friendly.

Hazardous Waste Classification and Disposal

Due to its petroleum origin and potential risk to the environment, asphalt cement waste is often classified as hazardous. Proper classification depends on specific characteristics including flash point, toxicity levels, and contamination with other hazardous substances. Commercial properties must conduct appropriate testing to accurately determine how waste should be classified.

Rather than just disposing of hazardous waste yourself, it must be transported by licensed professionals. These specialized companies possess required permits and equipment for safe transportation to approved disposal facilities. Commercial properties should verify transporter licenses and insurance coverage before engaging in services.

Disposal facility selection significantly impacts both cost and regulatory compliance. As a reputable commercial business, it’s important to choose facilities licensed for petroleum waste disposal that maintain appropriate environmental controls. Make sure to verify facility permits and environmental compliance records to avoid potential liability for improper disposal practices.

Documentation requirements for hazardous waste disposal include manifests, certificates of destruction, and chain-of-custody records. It’s essential to maintain complete documentation to meet regulatory inspection requirements and protect yourself against potential future liabilities. Many commercial properties benefit from partnering with waste management companies that handle documentation responsibilities as part of their service packages.

Spill Prevention and Emergency Response

Develop sophisticated spill prevention plans that address potential emergency scenarios during storage, handling, and transport operations. Such plans should include employee training, equipment maintenance, and inspections to identify potential problems before spills occur.

Emergency response protocols must address initial needs for containment, cleanup, and notification. Ensure spill response equipment absorbent pads, containment barriers, and personal protective equipment is readily available. And, educate personnel on proper response procedures and conduct frequent drills to prepare.

Reportage varies across jurisdictions but typically promptly notifying environmental authorities when spills exceed certain amounts. Commercial properties should have updated contacts of the relevant agencies and be aware of deadlines for reportage to enable them to respond in the event of an emergency.

Cleanup techniques require specialized equipment and methodology to prevent environmental contamination. Partner with qualified environmental remediation companies like

TMC Engineering that possess appropriate tools for concrete and asphalt cleanup activities. Proper cleanup prevents long-term environmental liability while minimizing business disruption. For more on this, check out our post “Tools for Concrete”.

Alternative Use Applications

Waste asphalt cement is often suitable in non-critical settings where lower-grade materials meet performance needs. Consider repurposing waste for temporary access roads, equipment pads, or other utility applications that provide value while avoiding disposal costs.

In other cases, some waste streams can work as dust suppressants for unpaved areas or construction sites. This application requires proper dilution and application but offers cost-effective, dust-control solutions for large commercial properties.

Industrial applications may accept waste asphalt cement for specialized purposes like equipment foundations, containment berms, or protective coatings. These applications often tolerate lower performance specifications while providing useful disposal alternatives that avoid hazardous waste classification.

Research emerging technologies that convert asphalt cement waste into alternative products. Innovation in this area continues developing new applications that may provide future disposal alternatives for commercial properties generating significant waste volumes.

Incorporating

fly ash into waste asphalt cement mixtures can produce useful materials for specific applications. This technique requires proper engineering analysis but offers a promising disposal solution for multiple waste streams simultaneously.

Managing asphalt cement waste effectively requires systematic approaches.

Effective asphalt cement waste management involves organized processes that balance regulatory compliance, environmental protection, and cost efficiency. Commercial buildings benefit from formulating comprehensive waste management plans that address all matters of generation, treatment, and disposal. Professional guidance by environmental consultants and waste management professionals guarantees compliance while maximizing cost-effectiveness.

Success depends on timely planning, proper execution, and ongoing monitoring of waste management operations. Businesses with proper waste management avoid regulatory violations and support environmental sustainability goals and public expectations.

At

TMC Engineering, we have a deep commitment to delivering projects characterized by the highest

standards for safety, workmanship, and client satisfaction. We aim to provide you with valuable content and insights related to the

services our

team of experts provides!

Whether you require

asphalt paving,

striping, or

concrete work, we offer a full suite of transportation construction solutions. Look no further we’ve got all you need and more!