Exposed Aggregate Concrete: A Complete Guide

Concrete work offers numerous opportunities for aesthetic and functional upgrading in the working environment. Exposed aggregate concrete has gained widespread acceptance in recent years because of its architectural possibilities and unique visual appeal.

Contractors are finding new and better ways of creating stunning exposed aggregate finishes, employing new technology and products to create individual surfaces that bring value to the property. This in-depth guide looks at what exposed aggregate concrete is all about and whether commercial property developers ought to consider this stunning alternative to their developments.

If you’d like a quicker or more specific answer to your asphalt or concrete repair questions, call the experts at TMC Engineering ! If you’re in Southern California, we can help educate you on your problem and perform whatever repair is necessary. We’ve got an expert solution for your commercial concrete or asphalt concerns!

What Is Exposed Aggregate Concrete?

Exposed aggregate concrete is a decorative concrete technique exposing the natural stones, pebbles, or other aggregate materials within the concrete mix by removing the outermost layer of cement paste. It creates a textured, pleasing surface that captures the natural beauty of the aggregate material in the concrete mix.

The process involves casting normal concrete with specially selected aggregate material and then exposing the aggregate by applying chemical retarders or washing methods before the total curing of the concrete. The outcome is an exposed surface where one can use decorative stones, colored glass, recycled glass, or natural pebbles as the focal visual feature.

Commercial buildings can gain from this process as it transforms ordinary concrete surfaces into stunning, durable features that require little maintenance while providing excellent slip resistance. The treatment works just as well on sidewalks, plaza areas, parking garages, and architectural details where functionality and aesthetics are important.

What Does Exposed Aggregate Concrete Look Like?

An exposed aggregate surface presents a mosaic-like appearance where individual stones, pebbles, or other aggregate materials create natural patterns and textures. The visual appeal depends entirely on the aggregate selection. River rock creates smooth, rounded patterns while crushed stone produces angular, geometric designs.

Several factors significantly affect the finished appearance:

- Aggregate Type and Size: Larger stones create bold, dramatic patterns while smaller materials produce subtle, refined textures. Natural river rock offers earth tones, while recycled glass provides contemporary color options.

- Exposure Depth: Shallow exposure reveals just the tops of aggregate pieces, creating a smooth surface with visible texture. Deeper exposure shows more of each stone, producing a more pronounced three-dimensional effect.

- Aggregate Distribution: Even distribution throughout the mix ensures consistent patterns, while concentrated placement in specific areas creates intentional design variations.

- Color Combinations: Mixing different colored aggregates or adding integral color to the concrete matrix creates complex visual effects that complement architectural themes.

Is Exposed Aggregate Concrete Durable?

Yes, exposed aggregate concrete is very durable if properly installed and maintained. The aggregate concrete itself is more wear-resistant than ordinary concrete surfaces because the exposed stones create a harder, abrasion-resistant surface.

The stones themselves that are exposed are usually harder than the cement matrix material, so they can better resist traffic and weather than the smooth concrete surfaces. This makes exposed aggregate particularly suitable for heavy-use commercial uses where durability has a direct influence on long-term maintenance expenses.

But longevity depends on the correct installation procedures, proper aggregates, and regular maintenance. Commercial structures must make contractors use the correct equipment to install concrete and follow standard procedures to achieve maximum lifespan. For more on this, check out our post, “Tools for Concrete.”

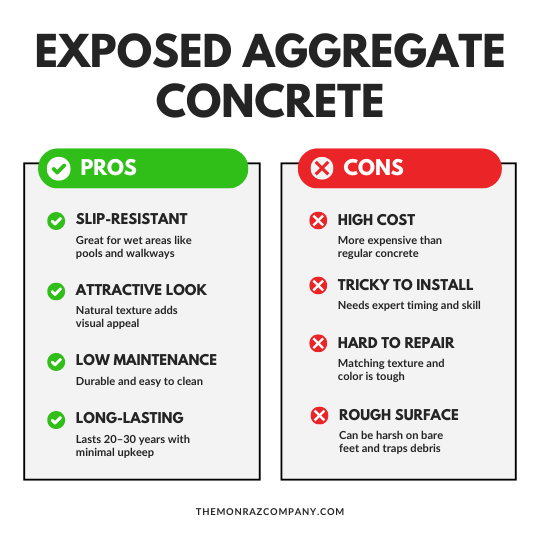

What Are The Benefits Of Exposed Aggregate Concrete?

Enhanced Slip Resistance

The textured surface created when you expose the aggregate provides excellent traction in wet conditions. This makes exposed aggregate particularly valuable for commercial properties where slip-and-fall liability concerns require superior surface grip.

Commercial walkways, pool decks, and entrance areas benefit significantly from this improved safety characteristic. The natural texture remains effective even when wet, unlike smooth surfaces that become dangerously slippery during rain or snow.

Superior Aesthetic Value

Decorative concrete products like exposed aggregate create eye-catching surfaces that increase property value and customer appeal. The natural beauty of specially selected aggregate material transforms functional concrete into architectural statements.

Commercial buildings use the process to create distinctive branding elements, complement matching building materials, or implement focused design schemes. The versatility allows for matching nearby architectural elements without compromising affordability.

Low Upkeep Needs

Under proper installation, exposed aggregate surfaces require less ongoing maintenance than other decorative treatments. The durability of the exposed stones enables colors to remain rich and textures to stay in position for decades with mere cleaning.

This low-maintenance feature is particularly gratifying to commercial property owners who have extensive areas like concrete driveways or plaza spaces where repeat maintenance would be costly and disruptive.

Longevity and Value

Properly installed exposed aggregate concrete will typically have a 20 to 30-year lifespan with minimal repair or refinishing. Such durability is cost-effective for use in commercial applications where replacement cost and business disruption must be minimized. Good exposed aggregate installation ensures reduced life-cycle costs and maintains property value over the long term.

What Are The Disadvantages Of Exposed Aggregate Concrete?

Higher Initial Cost

Creating quality exposed aggregate surfaces requires more labor, specialized materials, and careful timing compared to standard concrete installation. This translates to higher upfront costs that can strain project budgets.

Commercial property owners must weigh these initial expenses against long-term benefits and maintenance savings. While the investment proves worthwhile over time, immediate budget constraints may limit the feasibility of some projects.

Installation Complexity

The process of exposing the aggregate requires precise timing and technique. Contractors must carefully control the concrete curing process and use proper washing techniques to achieve consistent results across large areas.

Inexperienced installation teams may produce uneven exposure, patchy appearances, or structural issues that compromise both aesthetics and durability. Commercial projects require qualified contractors with proven exposed aggregate experience.

Repair Challenges

When damage occurs to exposed aggregate surfaces, repairs prove more complex than standard concrete fixes. Matching aggregate materials, colors, and textures requires specialized skills and materials that increase repair costs.

Commercial properties should establish maintenance protocols specifically designed for exposed aggregate surfaces and identify qualified repair contractors before issues arise.

Surface Roughness

While the textured surface provides excellent slip resistance, it can prove uncomfortable for bare feet and may catch debris more readily than smooth surfaces. This characteristic may limit suitability for certain commercial applications.

Areas, where customers might sit, walk barefoot, or place items directly on the surface, require careful consideration of aggregate size and exposure depth to balance safety with comfort.

How To Do Exposed Aggregate Concrete

Step 1: Prepare the base and mix design.

Establish proper subgrade preparation and create a concrete mix design incorporating the selected decorative aggregate materials. The aggregate should comprise 15-20% of the total mix volume for optimal exposure results.

Step 2: Place and level the concrete.

Pour the concrete mixture using standard placement techniques, ensuring an even distribution of aggregate materials throughout the surface. Use screeds and bull floats to achieve proper grade and surface smoothness.

Step 3: Apply surface retarder.

Step 4: Expose the aggregate.

Once the concrete reaches proper firmness, use water spraying and brushing techniques to remove the retarded cement paste and expose the aggregate materials. This critical step requires careful timing and technique.

Step 5: Clean and seal.

After complete curing, clean the surface thoroughly and apply appropriate sealers to protect the exposed aggregate surface and enhance color retention.

How Much Does Exposed Aggregate Concrete Cost?

Exposed aggregate concrete typically runs $8-15 per square foot for commercial applications compared to $4-8 per square foot for standard concrete. This is a result of the additional materials, work, and expertise required for quality outcomes.

The following factors impact actual project costs:

- Aggregate Selection: Expensive items like colored glass or exotic stone may double project costs when compared to the use of standard river rock or crushed stone options.

- Project Size: Larger installations benefit from economies of scale, reducing cost per square foot for big commercial projects.

- Site Conditions: Rough access, extreme shapes, or tricky site conditions increase labor expense and project difficulty.

- Contractor Experience: More experienced contractors are more expensive but offer better quality work with fewer callbacks and warranty claims.

- Design Complexity: Simple, uniform patterns are cheaper than complicated work with multiple types of aggregates or intricate pattern work.

The bottom line is that commercial property owners should budget ahead for quality installation with trusted and capable contractors like TMC Engineering rather than going for the cheapest price. Accurate installation has a direct impact on long-term performance and appearance.

Exposed aggregate concrete is very durable if properly installed and maintained.

Quality exposed aggregate concrete yields decades of attractive hard service. It also enhances the property value and saves you avoidable maintenance fees in the long term. For more information about concrete materials and maintenance, check out our related articles, “Concrete Slab Foundation Repair” and “Concrete Parking Lot Repair.” For more information on how to deal with other issues on concrete, you can also visit our blog.

At TMC Engineering, we have a deep commitment to delivering projects characterized by the highest standards for safety, workmanship, and client satisfaction. We aim to provide you with valuable content and insights related to the services our team of experts provides!

Whether you require asphalt paving, striping, or concrete work, we offer a full suite of transportation construction solutions. Look no further-we’ve got all you need and more!