Upgrade Your Curb Appeal with a Stained Concrete Driveway

Concrete is a popular paving material for driveways due to its durability and affordability. Concrete holds up well against weathering, requires little maintenance, and offers a long service life. The functional ity of concrete make s it a sensible choice for any high traffic area.

However, one drawback of basic concrete is its lack of aesthetic appeal. A bare concrete driveway is visually dull , uninteresting, and cold. This can compromise the overall look of a property, reducing the perceived value.

Fortunately, there are numerous cost-effective techniques to transform drab concrete and take a driveway’s look to the next level. One such option is staining, which allows concrete to be both practical and design-forward, complementing the architecture and landscaping.

Today, this post is dedicated to concrete driveway stain – an affordable way to breathe new life into plain concrete slabs. Staining is a versatile and budget-friendly solution to mimic higher-end surface options like marble, tile, or stone, dramatically upgrading a driveway’s visual interest and curb appeal. Here’s our guide to stained concrete driveways:

If you’d like a quicker or more specific answer to your possible questions about stained concrete driveways, call the experts at TMC Engineering ! If you’re in Southern California, we can help educate you on your problem and perform whatever repair is necessary. We’ve got an expert solution and expert contractors that can handle any concrete concerns!

Upgrade Your Curb Appeal with a Stained Concrete Driveway

A stained concrete driveway refers to coating an existing concrete surface with penetrating dyes or acid-based stains to achieve a customized, multi-tonal look. This is a versatile and affordable way to transform a plain concrete driveway into a beautiful focal point at your property’s entrance or parking area .

Staining allows the concrete’s natural beauty to shine through with added depth and dimension from mineral pigments. It allows you to mimic higher-end looks like marble, stone, tile, or wood grain patterns without the prohibitively high costs. Whether in subtle blended tones or dramatic multi-colored veining, penetrating stains breathe new life into drab concrete.

The results significantly upgrade a driveway’s curb appeal through customized multi-tonal palettes. All of this is achievable at a fraction of replacement costs. Plus, staining will not compromise the concrete’s durability or functionality. It creates a luxurious finished surface that rivals more expensive materials without busting your budget.

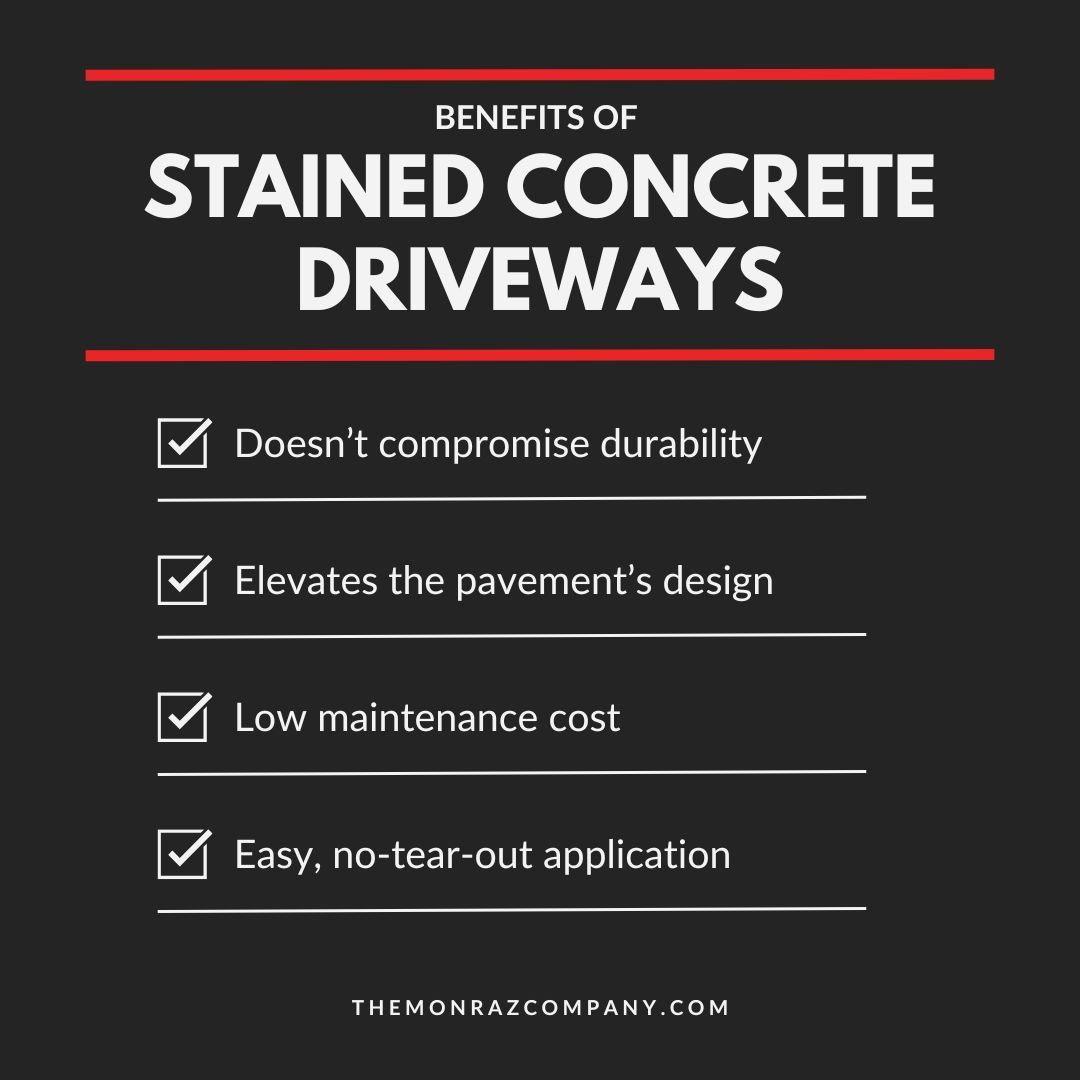

Benefits of Stained Concrete Driveways

- Doesn’t compromise durability

- Elevates the pavement’s design

- Low maintenance cost

- Easy, no-tear-out application

How To Stain Concrete Driveways

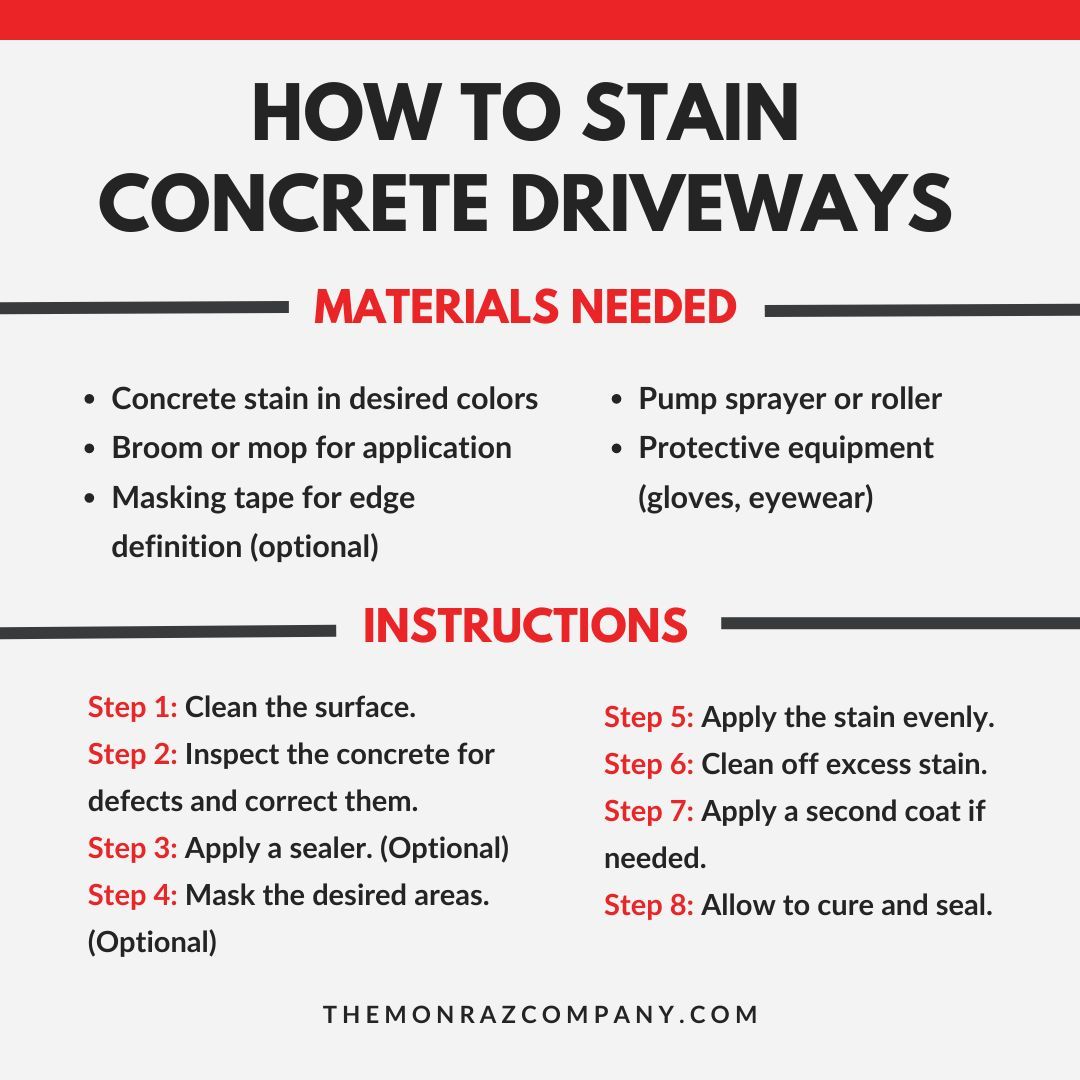

Materials Needed

- Concrete stain in desired colors

- Broom or mop for application

- Masking tape for edge definition (optional)

- Pump sprayer or roller

- Protective equipment (gloves, eyewear)

Instructions

Step 1: Clean the surface.

Thoroughly pressure wash the entire concrete surface to remove any dirt, debris, oil deposits, or existing sealers that may prevent the stain from absorbing properly. Use a degreasing cleaner if needed to fully clean grease spots. Allow the concrete to completely dry for 48 hours before proceeding.

Step 2: Inspect the concrete for defects and correct them.

Check for any minor cracks or defects in the concrete and fill them using a concrete crack filler. This will help prevent the stain from seeping into the cracks and spreading unevenly.

Step 3: Apply a sealer. (Optional)

For extra protection of the stained surface, apply a high quality concrete sealer . This will fill pores in the concrete to ensure an even application and absorption of the stain.

Step 4: Mask the desired areas. (Optional)

Use tape if staining areas with distinct boundary lines between shades. Tape off any areas that you do not wish to be stained.

Step 5: Apply the stain evenly.

Using a pump sprayer or roller, apply an even coat of acid-based or water-based stain to the entire concrete surface according to manufacturer’s instructions. Work in small sections for optimum coverage.

Step 6: Clean off excess stain.

Lightly wipe away any excess stain that has pooled on the surface using a clean rag or sponge to achieve uniform penetration.

Step 7: Apply a second coat if needed.

Reapply stain in light, even coats for deeper color development.

Step 8: Allow to cure and seal.

Let stained concrete dry completely before permitting use. Then apply a high-quality, UV-resistant topcoat sealer to protect your new look.

Stained concrete driveways provide a cost-effective way to transform drab concrete into a n extension of your property’s landscaping and architecture.

Using inexpensive customized multi-tonal stain pallettes, you can upgrade your concrete slab with minimal effort. Whether you want something that evokes luxury like faux marble or something rustic like wood, acid stains make that possible using the concrete’s natural striations. If you’re wanting to go even bolder, read our post on stamped concrete paint and the best paint for concrete driveway. You can achieve so many looks beyond the standard gray slab! Time to get creative with colored concrete!

Here at TMC Engineering , we have a deep commitment to delivering projects characterized by the highest standards for safety , workmanship, and client satisfaction.

We aim to provide you with valuable content and insights related to the services our team of experts provides! Whether you require asphalt paving , striping, sealing , or concrete work , we offer a full suite of transportation construction solutions. Look no further we’ve got all you need and more!