Asphalt Driveway Edging for Clean, Long-Lasting Pavement

Asphalt is a very popular paving material for driveways due to its affordability and durability. Asphalt driveways provide a hard, smooth surface that can withstand the wear and tear of regular use and weathering . They are economically priced compared to other paving options like concrete . You can read more on the differences between both materials in our post on asphalt vs concrete parking lots .

Asphalt is flexible, allowing it to expand and contract with temperature changes without cracking. However, one drawback of asphalt is that it is prone to spilling over the edges of the driveway if not properly contained. Over time, asphalt can spill unattractively into surrounding landscaped areas if the edges are not well-defined. This can detract from the curb appeal of the home and yard. Additionally, if asphalt is allowed to spill over the sides, it can eventually break up and deteriorate more quickly, shortening the lifespan of your driveway.

To prevent asphalt overflow and maintain a clean, long-lasting driveway, it is important to properly edge the asphalt. Edging creates a barrier that contains the asphalt and keeps its shape. Today, this post is dedicated to discussing asphalt driveway edging. We will explore what edging is, provide instructions on how to edge an asphalt driveway, and share some edging ideas to help protect your investment and ensure your asphalt driveway maintains its beauty for many years to come.

If you’d like a quicker or more specific answer to your questions about asphalt driveway edging, call the experts at TMC Engineering! If you’re in Southern California, we can help educate you on your problem and perform whatever repair is necessary. We’ve got an expert solution and expert contractors that can handle any concrete concerns!

What Is Asphalt Driveway Edging?

Asphalt driveway edging refers to any material used to border the perimeter of an asphalt surface. Edging an asphalt driveway involves lining the outside edges with a contained barrier to prevent the asphalt paving from spilling over onto surrounding landscaped areas. This is important regardless of the materials used1 There are different types of asphalt used for different reasons and conditions. Yet, edging is still important for quality, long-lasting driveways irrespective of the material.

It is important to properly edge an asphalt driveway to prolong its lifespan. Edging creates a defined edge that contains the asphalt, keeping it from overflowing in uneven, broken patches over time. This helps the driveway retain its shape , durability, and appearance. It also protects nearby plants and grasses by preventing the asphalt from encroaching onto lawn and garden spaces.

By maintaining its structure and uniformity, driveway edging increases curb appeal to enhance the property’s value and reputation. Any asphalt paving projects should involve edging for the biggest short- and long-term benefit.

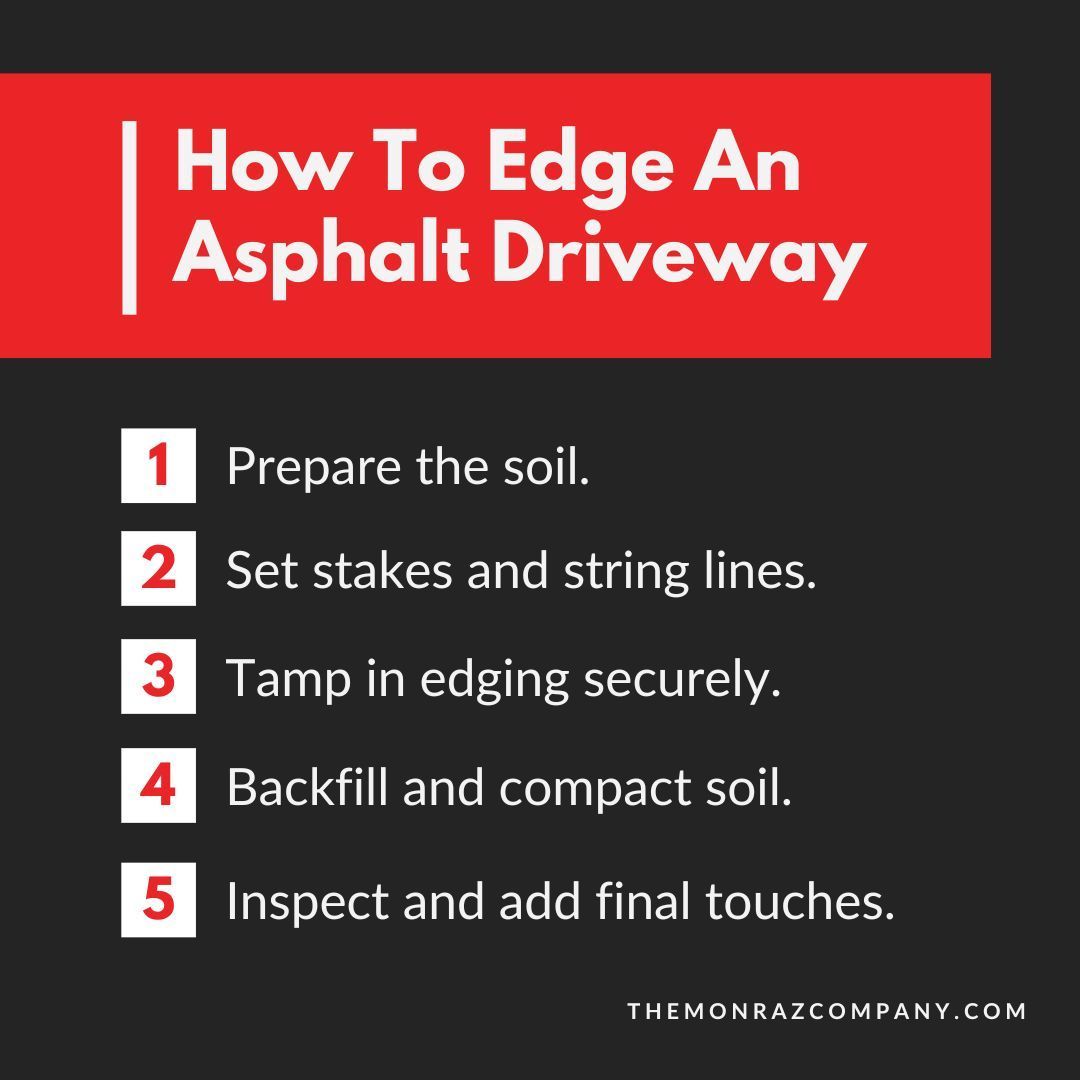

How To Edge An Asphalt Driveway

Step 1: Prepare the soil.

Before installation, loosen 6-8 inches of soil where edging will contact the ground using a spade or edger. This eases embedding materials securely later.

Step 2: Set stakes and string lines.

For straight-edged borders, stretch mason’s strings between stakes as guides positioned just outside where the edging will lie.

Step 3: Tamp in edging securely.

Gently hammer bordering into the soil approximately 1-2 inches deep, checking level and straightness against guide strings. Tamp soil firmly around the material.

Step 4: Backfill and compact soil.

Refill excavated soil and pack tightly against edging using a tamper for strong anchoring against movement from weathering.

Step 5: Inspect and add final touches.

Add decorative mulch, plantings or pavement edging sealant as desired once compaction cures for a finished look enhancing curb appeal.

Asphalt Driveway Edging Ideas

Natural Stone

Natural stone edging such as flat flagstones creates an elegant border. The stone withstands weathering well without cracking. Over time, it may develop an attractive aged patina. This durability helps ensure the edging will withstand climate fluctuations and prevent asphalt spillover for decades.

Plastic Edging

Inexpensive plastic edging provides a clean, contained edge for the budget conscious. While it may not last as long as stone, for some applications, it can fulfill its role for several years before needing replacement.

Poured Concrete

Poured concrete edging can be molded into decorative shapes, adding architectural flair. Its rigid structure anchors firmly against movement. This helps maintain a defined edge protecting the asphalt pavement from breaking down prematurely.

For more on this, you can look through our considerations in our post on “ When Can You Pour Concrete?”.

Landscaping Timbers

Rough sawn timbers, like cedar planks, add natural beauty. The se material s withstand settling and splitting better than loose materials. Combined with landscaping , this edging option enhances curb appeal while guarding the asphalt edge long-term.

As you can see, there are several asphalt edging options. Natural stone like flagstone creates a stately border. Plastic forms an affordable contained edge. Poured concrete lends permanence and architectural possibilities. Landscaping timber incorporates beauty and structure. All provide a defined edge that maintains the driveway in pristine condition at the edge of the driveway.

By selecting durable edging that withstands settling and climate cycles, you can extend the life of your asphalt investment significantly. Periodic resealing will result in less intensive maintenance over the years.

Well-edged asphalt enhances a home’s curbside curb appeal and resale value.

By selecting and installing the right edging solution tailored to your property’s characteristics and personal taste, you can shelter your asphalt investments while maximizing longevity and returns. Let us help you design, supply and execute flawless edgework allowing your driveway upgrade to shine for many satisfying years ahead!

Our team of experienced paving professionals at TMC Engineering provides a wide range of transportation construction services to meet all of your project needs. Whether you needasphalt paving, striping, sealing, or concrete work completed, we have the expertise and equipment to handle the job efficiently and cost-effectively. By combining extensive industry knowledge with high-quality materials and workmanship, we can deliver durable, long-lasting results!

Contact us today to discuss your requirements and receive a customized proposal. We aim to forge strong partnerships through collaboration on quality-focused solutions!

Visit the blog for more articles from the TMC experts: