How Long Does Asphalt Take To Dry?

Installing new asphalt pavement involves meticulous multi-step work from preparing the site and material delivery to shaping, compacting, and finishing the surface. Once completed, freshly paved driveways, parking lots, or roads provide an attractive, durable surface for vehicular use. However, there is an important factor to consider regarding the use of new asphalt — its drying and curing timeline.

Misconceptions about the behavior of asphalt often lead to unintended consequences, particularly concerning its perceived drying process. Contrary to popular belief, asphalt doesn’t “dry” in the traditional sense like water-based coatings; instead, it undergoes a curing process. This misunderstanding can have significant implications, especially when it comes to determining when newly laid asphalt is ready for traffic and other activities. In this discussion, we’ll debunk the myth of asphalt drying and explore the crucial factors involved in ensuring the optimal performance and longevity of freshly laid pavement. Understanding these dynamics is essential for property owners, contractors, and anyone involved in asphalt installation and maintenance to make informed decisions and prevent costly mistakes.

In this post, we will explore the natural processes involved in asphalt curing. Specifically, we will address how long it takes for asphalt to fully cure under typical conditions. The impacts of various weather factors will also be examined. If you’re in Southern California and would like a quick, clear answer that’s specific to your location and climate, please just give us a call at TMC Engineering for expert advice and a free quote!

How Long Does Asphalt Take To Dry?

Drying refers to the evaporation of water. Asphalt does not contain any water because it reaches temperatures up to 275-325 degrees when laid, causing any water on or in the asphalt to evaporate. Therefore, it must cool, not dry.

That said, to answer the question, it is important to correct it first: How long does asphalt take to cure?

Typically, it takes asphalt surfaces 48-72 hours (about 3 days) under ideal conditions, to curate long enough for the asphalt to withstand vehicles. However, below the surface, more complex chemical reactions are at work as the asphalt mixture transforms into a durable pavement capable of withstanding sustained traffic loads.

Fully cured asphalt spans around 30 days to complete. During curing, the asphalt binder oxidizes and crosslinks with aggregates to gain strength ad flexibility. Multiple factors influence curing times, such as weather, season, formula, material temperature, and pavement thickness. Additionally, cure time may be hastened or slowed depending on compaction methods , additive use, and present site temperature.

While driving on asphalt a few days after installation can be done cautiously, contractors recommend avoiding heavy loads until curing concludes to let the asphalt fully develop its designed characteristics. Only by understanding the curing stage involved with asphalt installation can property owners and crews make informed decisions about activity timing to protect their pavement investments long-term.

Weather Impacts On Asphalt Curing Time

Sunlight

Direct sun greatly speeds up the oxidation process that hardens asphalt. Sunbathing those first days accelerates drying as opposed to cloudy weather, which prolongs it.

Temperature

Warmer ambient temperatures above 60°F allow faster drying versus cooler conditions. If the temperature is between 40-50°F that increas es the drying and curing window to 3-5 days. Freezing conditions can complicate matters, with most contractors scheduling spring through fall for best results.

Rainfall

If possible, avoid heavy rain for 48 hours after paving as standing water infiltrating the asphalt can dissolve binders or create runoff weaknesses discussed in our post on concrete repair . Light-scattered showers seem less impactful to the process.

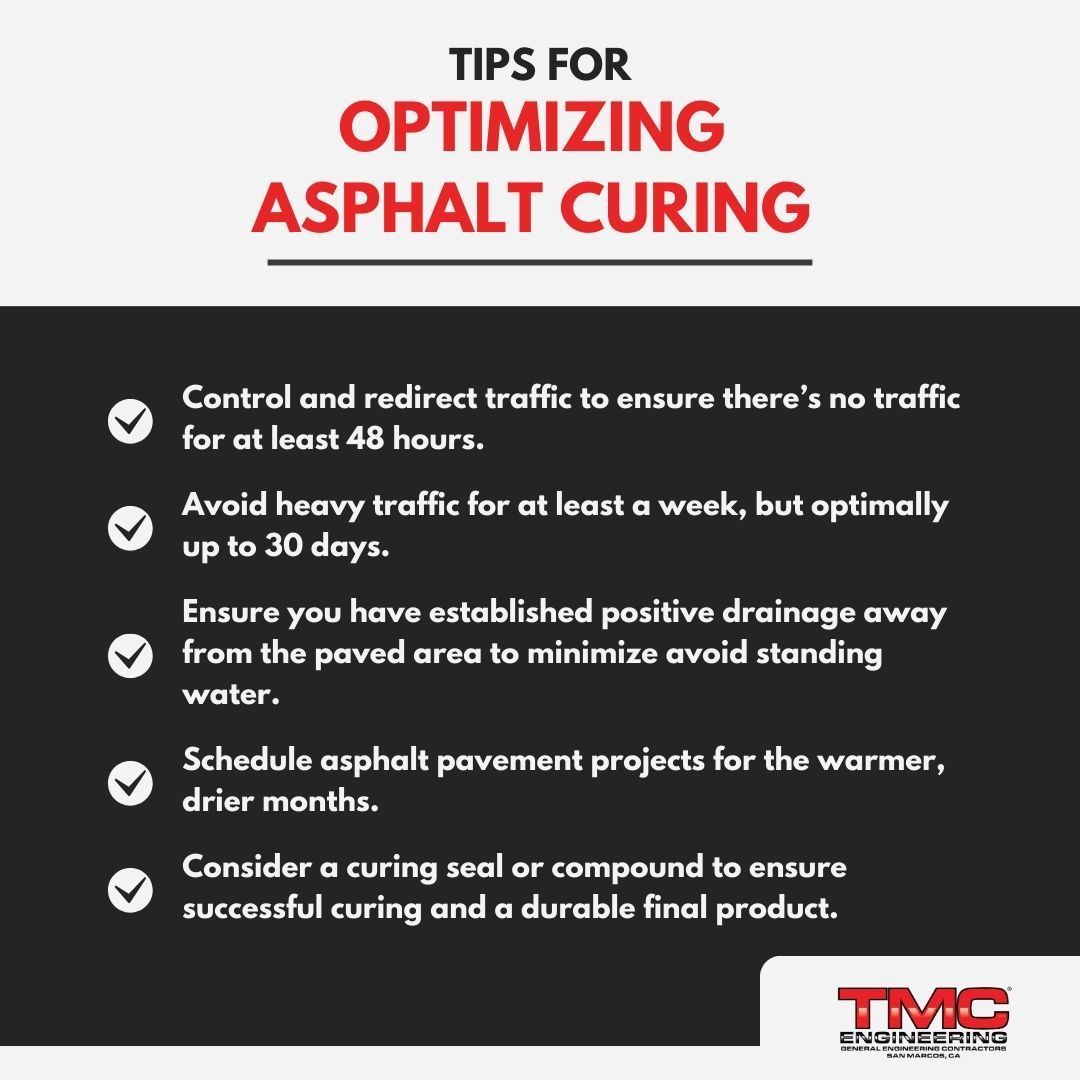

Tips for Optimizing Asphalt Curing

Control early traffic.

Barricade fresh asphalt areas and post warning signs to restrict use for at least 48 hours. After initial curing, direct traffic toward the edges of your newly laid pavement foremost. This area will be ready for use sooner than the rest.

Try to avoid heavy traffic.

Avoid driving heavy vehicles like trucks and equipment on new asphalt for at least a week (but up to 30 days for best results) to allow the surface to fully cure. Light passenger vehicles are okay after 2-3 days as long as low speeds are maintained.

Minimize standing water.

Ensure you have established positive drainage away from the paved area prior to the project to prevent water from pooling on the surface. This keeps the asphalt mixture from getting saturated, which can negatively impact the pavement’s development of structural integrity.

Coordinate the weather windows.

Schedule your paving for warmer, drier weather when possible . H eat and sunshine accelerate curing , so these conditions will be optimal for curing . You can monitor forecasts and be prepared to protect new asphalt from precipitation using tarps if necessary.

Make use of curing compounds and seals.

An asphalt curing seal can act as a barrier against water, UV rays, and other damaging elements for a more effective cure and a more durable final project. Both can increase your chances of a successful cure. If rainfall occurs within 2 hours of either initial application, reapply.

Though asphalt may appear “dry” after a couple days, it still needs to undergo the full drying and curing process before it’s ready for use.

In summary, while asphalt may feel dry within a day, the full curing process continues for approximately 30 days as the complex chemical compositions fully develop strength and durability . While light use can begin cautiously after 2-4 curing days, completely curing ensures smoothness, durability , and 50+ year life spans discussed in our posts on infrastructure projects.

Following drying/curing timelines prevents accelerated wear and potential cracks from overloading fresh mixtures. With prudent planning factored in, asphalt will serve your property well for decades.

We hope this overview on drying time frames proves useful in protecting both your investment and equipment! Don’t hesitate to contact us for all your expert paving needs!

Here at TMC Engineering , we have a deep commitment to delivering projects executed using the highest standards for safety , workmanship, and client satisfaction. We aim to provide you with valuable content and insights related to the services our team of experts provides! Whether you require asphalt paving, striping, sealing, or concrete work, we offer a full suite of transportation construction solutions. Look no further — we’ve got all you need and more!