Can You Seal Coat in Cold Weather?

Seal coating is an important maintenance technique that protects and preserves asphalt pavement surfaces. It involves spraying a thin liquid layer of asphalt emulsion sealer over existing asphalt to fill minor cracks and seal out moisture penetration. This keeps underlying layers intact and pavement flexible.

As discussed in our post on best weather for asphalt paving , for optimal best results, seal coating is typically done in warm, dry conditions between 55-80 degrees Fahrenheit , allowing the sealer proper time to dry and cure. However, there are reasons one may need to apply sealers in colder weather as well, so let’s discuss the possibility of sealing coats in cold weather.

However, if you’d rather fast forward and get a direct answer and quote on your Souther California commercial asphalt project, Before you dive in, if you’re ready to take the leap on your commercial asphalt project in Southern California, contact us today for a FREE QUOTE !

Can You Seal Coat in Cold Weather?

Most seal coatings are water-based asphalt emulsions , meaning small droplets of asphalt cement are suspended in water. In colder temperatures below around 55 degrees, the drying time for these sealers greatly increases as the water is slower to evaporate. There is also a higher risk of the sealer drying before fully curing and bonding to the pavement surface. This can cause inadequate protection, early cracking, or flaking off within a couple of years. So , in general, it is not optimal to apply seal coats in temperatures lower than 55 degrees.

Sealers designed to operate effectively at cooler temperatures, reaching down to approximately 40 degrees, are available. These utilize different solvents or polymers to maintain flexibility at lower temperatures while still protecting the pavement. Using the right cold-weather grade sealer matched to the forecast prevents issues associated with standard sealers drying too quickly in the cold. But there are still factors to consider , like scheduling and contractor experience.

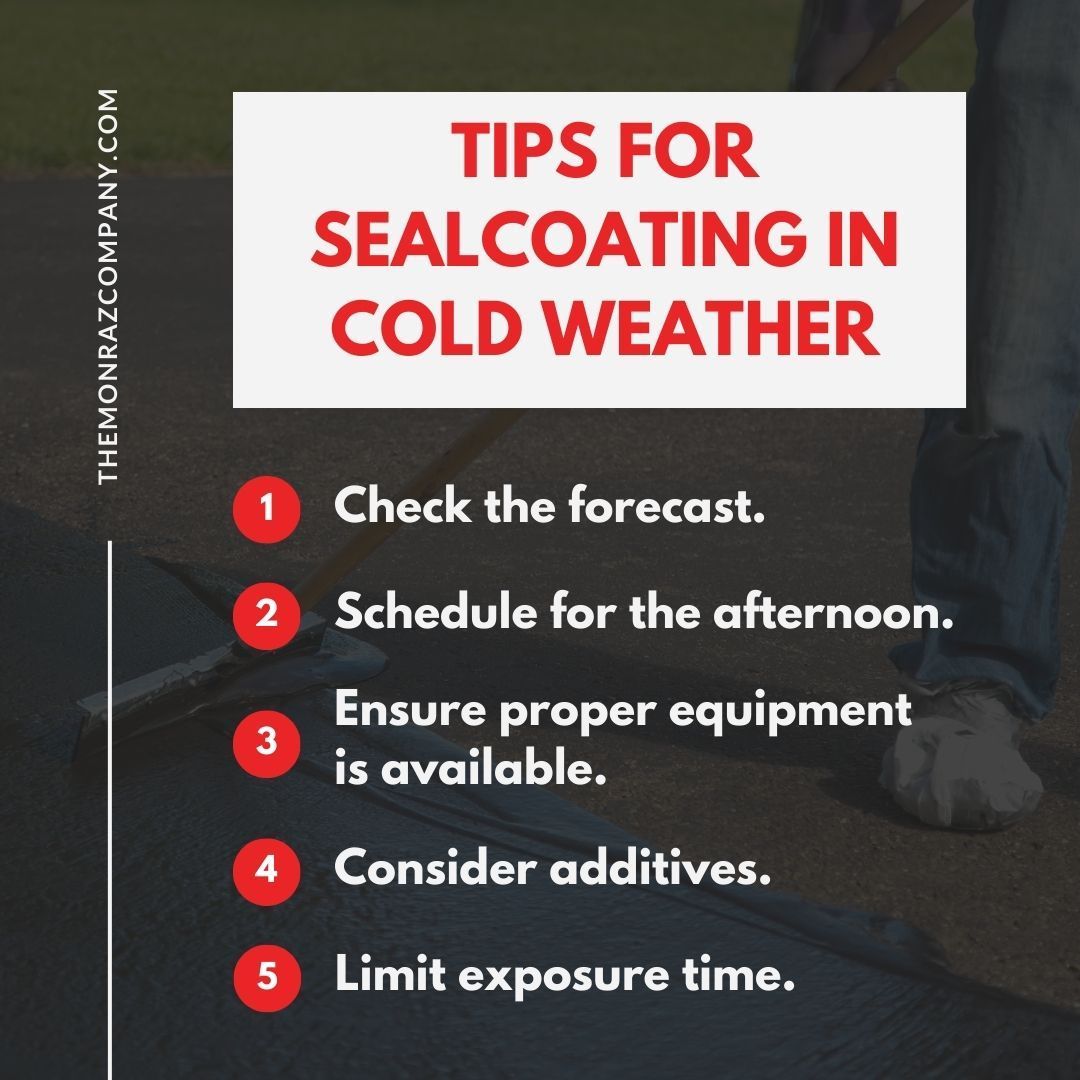

Tips For Sealcoating In Cold Weather

Check the f orecast .

Only apply sealers if the following 3-4 days will be rain/snow free and temperatures remain above the manufacturer’s minimum requirement, usually 40 degrees F. Avoid seal coating if precipitation is in the forecast.

Schedule for the a fternoon .

Morning applications increase the risk of coatings drying too fast as temperatures rise through the day. Afternoon projects allow full curing before overnight temperature drops.

Ensure p roper e quipment is available.

Thicker cold-temperature grade sealers may require the utilization of specialized spray equipment for proper application. Contractors should also have heaters to warm sealers as needed.

Consider a dditives .

Some sealers contain accelerators promoting quicker drying even in cooler weather. Contractors experienced with specialized formulas get the best results.

Limit e xposure t ime .

Cold temperatures shorten the window for even and thorough application. Consequently, experienced crews can work faster to avoid partially dried coatings in changing conditions. Additionally, swift application by skilled professionals becomes imperative in colder weather to ensure a consistently effective coating.

With the right sealer, conditions, equipment, and experienced contractor, seal coating is possible even in cooler fall or spring weather to protect pavement year-round. But for the most consistent results meeting warranty standards, it is generally best to schedule during warmer season months if possible.

Seal coating is best done around 55 degrees for optimal results.

In conclusion, while not optimal, seal coating can be done when temperatures are near or slightly below 55 degrees , using specialized cold-weather grade seal coatings. Checking the forecast, available equipment, contractor qualifications, and appropriate curing time can help ensure the coating fully bonds.

For the best long-term results, though, scheduling seal coating projects is best during seasonally warm and dry weather above 55 degrees.Doing so maximizes the sealer’s protective performance throughout its service life.

Whatever your asphalt pavement needs are , relying on professionals like TMC Engineering ensures fast, compliant work addressed by certified crews with proper removal know-how. Hiring an asphalt and concrete contractor like us saves you from the dangers and difficulty of do-it-yourself removal with heavy machinery!

Our team has the proper training, equipment, and expertise to efficiently complete this physically demanding phase. Contact us today for your FREE QUOTE!