Asphalt Removal: What It Is & Why You Would Need It

Removing existing asphalt surfaces is no small undertaking, whether you’re a homeowner embarking on a driveway removal or a contractor demolishing a large parking lot. Aside from being physically demanding work, asphalt removal can seem like a formidable and costly project to take on!

Asphalt serves us well by providing durable, long-lasting pavement surfaces, as highlighted in our post “ How is Asphalt Made ”. But as our post “ Different Types of Asphalt ” describes, even the most well-maintained pavement will eventually show signs of wear after years of weathering and usage. As it ages, asphalt often requires replacement due to issues like cracking , deterioration, structural failures, or safety hazards.

When choosing between repairing failed asphalt or starting fresh with removal and replacement, the latter may prove more cost-effective in the long run. Tackling full demolition also allows for upgrading materials , which can be tailored to current needs. With companies dedicated to asphalt construction and demolition, removal jobs no longer need to be avoided due to perceived difficulty!

In this post, we’ll delve into what asphalt removal involves and why the process may be warranted. We’ll also outline best practices for proper asphalt demolition , whether undertaking the job yourself or hiring a contractor for the work!

Before you dive in, if you’re ready to take the leap on your commercial asphalt project in Southern California– contact us today for a FREE QUOTE!

Asphalt Removal – What It Is and Why You Would Need it

Asphalt removal, also called asphalt demolition, refers to the process of breaking up and removing existing asphalt pavement. This may involve completely removing layers of asphalt or just taking off the top surface layers. The removal process readies the base for a new asphalt installation or alternate paving material .

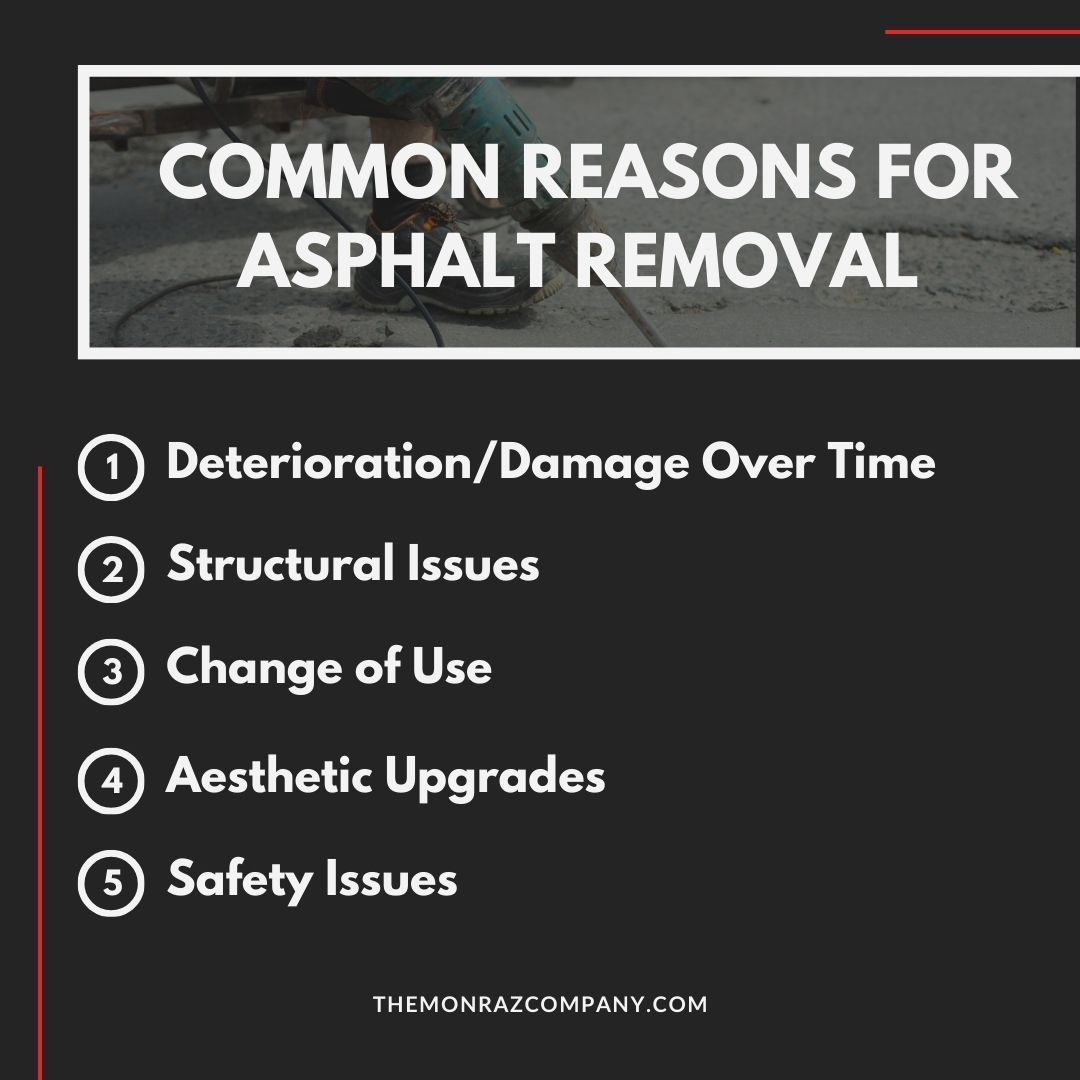

Some common reasons for removing asphalt include:

- Deterioration/Damage Over Time: Asphalt endures cracking, rutting, oil stains, and other signs of aging after 10-15 years of use depending on climate and maintenance.

- Structural Issues : Asphalt may need replacing if the base or subgrade has become uneven or unstable from degradation.

- Change of Use: Removal is necessary when renovating a space for a new purpose , like converting a parking lot to green space.

- Aesthetic Upgrades: Owners may remove asphalt for cosmetic improvements like installing decorative pavers or stamped concrete.

- Safety Issues : Removal allows repairs to trip hazards, large cracks, or other problems compromising safety.

Proper asphalt removal preps the surface for a new asphalt layer, different paving material, or ground cover with a stable base. It’s a critical early step regardless of the project scope or material chosen!

For extensive areas, consider renting or purchasing larger skid steers, excavators, or feller bunchers for faster, safer breaking and loading of asphalt pieces. Some jobs involve concrete removal as well as the other materials bonded to the asphalt. Specialized equipment like demolition saws and jackhammers expedite the safe extraction of composite surfaces during concrete or masonry removal.

How To Remove Asphalt

Step 1 – Mark the Perimeter

Use marking paint to draw a line along where the existing asphalt meets other surfaces like curbs or landscaping. This prevents accidental damage to surrounding areas.

Step 2 – Make Cuts

For large removal areas, make straight cuts through the asphalt using a concrete saw. Cutting facilitates breaking the asphalt into manageable pieces for removal.

Step 3 – Break Up the Asphalt

Use pavement breakers, backhoes, excavators, or similar heavy equipment to shatter and pry away pieces of asphalt within the cut lines. You can go in a methodical pattern!

Step 4 – Load and Haul Away

Load debris onto dump trucks or trailers for disposal following your local regulations. Properly disposing of materials minimizes environmental impacts.

Step 5 – Inspect the Base

Check the condition of the underlying material , like aggregate base. It may need re-grading, adding, or replacing prior to repaving.

Step 6 – Finish Prepping the Site

Sweep or blow remaining asphalt crumbs; ensure the base is dry, compacted, and ready for the next phase , whether paving or finishing with another surface material.

With forethought in preparation, equipment choice, and removal techniques, even complex demo jobs are achievable. Good planning is half the battle to success. At TMC Engineering, quality removal is our specialty for any project scope involving asphalt or concrete demolition!

Asphalt removal can be an easy task when done by the right hands.

In summary, asphalt removal necessitates breaking up and hauling away existing asphalt to make way for repaving, new materials, or land use changes. Hirin g licensed contractors experienced in removal techniques assures safety protections, fast results, and proper waste disposal procedures. Their expertise streamlines this important early phase, whether eliminating minor cracks or preparing vast lots for redevelopment. With advanced planning and the right equipment operated by skilled hands, asphalt demolition proves an achievable obstacle for any project scope!

With a need arising to remove an asphalt driveway or parking area, relying on professionals like TMC Engineering ensures fast, compliant work addressed by certified crews with proper removal know-how. Hiring an asphalt and concrete contractor like us saves you from the dangers and difficulty of do-it-yourself removal with heavy machinery!

Our team has the proper training, equipment, and expertise to efficiently complete this physically demanding phase. Contact us today for your FREE QUOTE!