Driveway Drain Grate: Everything You Need to Know

A well-designed and properly installed drainage system is crucial for any driveway to prevent flooding and water damage. It helps redirect excess water away from the driveway, where it can drain safely into a soakaway pit or leach field through underground pipes. This protects against issues like uneven puddling or premature pavement deterioration .

While drains effectively move water off the driveway surface, they still need protection from debris that could clog the drain opening over time. This is where installing a driveway drain grate serves as a valuable part of your overall drainage solution. A grate protects drains from debris while allowing water to flow freely into the system, ensuring it continues working effectively for years to come.

In this post, we will provide an overview of driveway drain grates, exploring what they are, their benefits, and how to properly install one to safeguard your drainage system intake.

However, if you’d rather fast forward and get a direct answer and quote on your Southern California commercial asphalt project, contact us today for a FREE QUOTE !

What is a Driveway Drain Grate?

A driveway drain grate is a protective cover placed over the opening of a surface drain outlet. Typically , it is made of durable materials like galvanized steel, cast iron, heavy-duty plastic, or reinforced concrete. Drain grates feature a slotted or grated surface pattern to allow water to flow smoothly while ensuring that debris doesn’t pass through. This helps to prevent clogging of the drain , which could lead to backups and flooding issues in the long run.

Driveway drain grates are beneficial additions to any drainage system, serving two critical functions. First, they filter out leaves, gravel, and other materials that may enter the drain opening. Second, they are strong enough to withstand regular traffic from vehicles and other heavy equipment, without breaking or collapsing into the drain below , which could cause damage not only to the drain, but to the machinery . Th e load-bearing material ensures the drainage system’s intake remains clear and water can flow unobstructed into the piping network below.

Opting for a properly sized and installed driveway drain grate is an important maintenance consideration. It helps to safeguard any drainage system’s long-term performance and protect surrounding pavement and landscaping from potential water damage issues. They provide simple but effective protection for subsurface drains and soakaways.

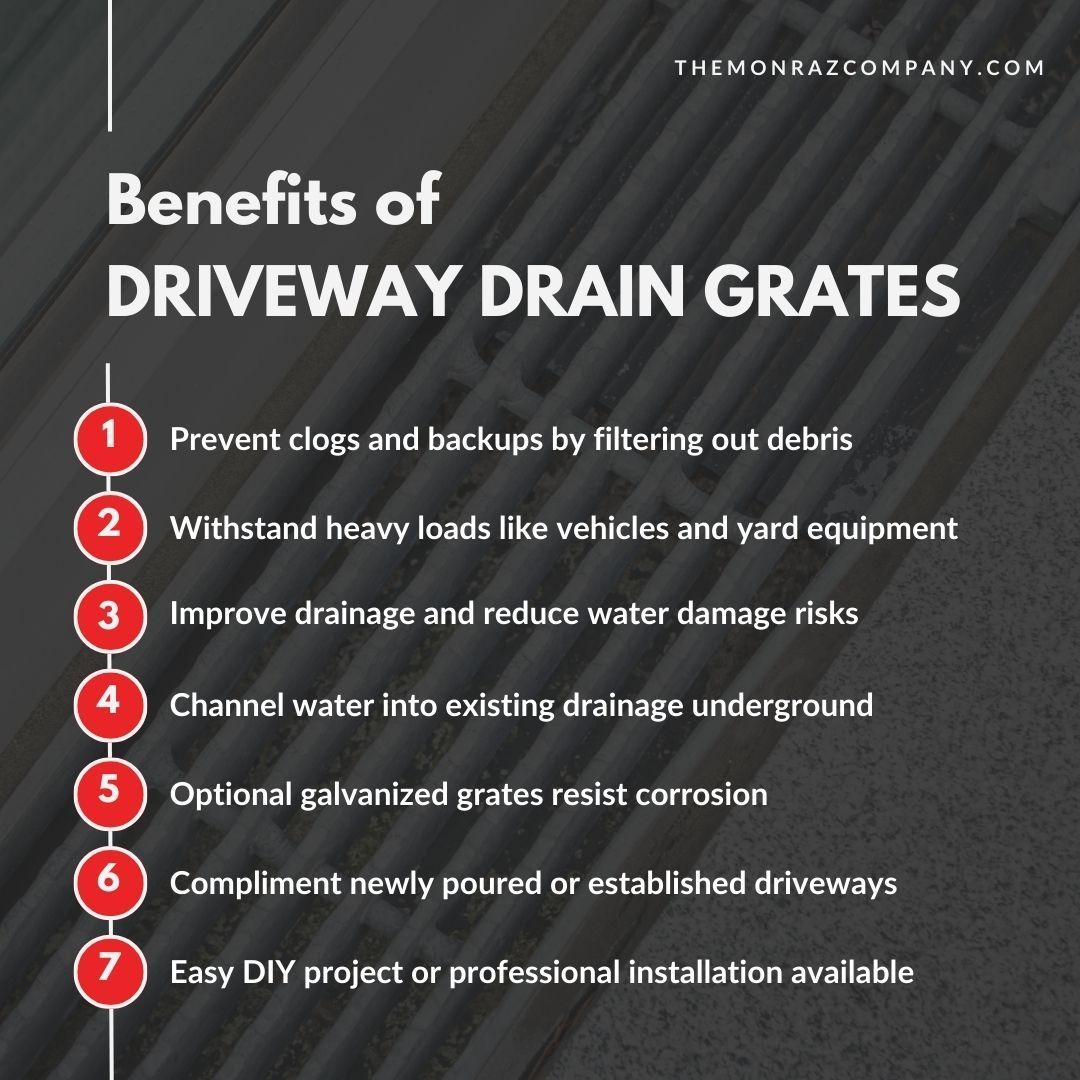

Benefits of Driveway Drain Grates

- Prevent clogs and backups by filtering out debris

- Withstand heavy loads like vehicles and yard equipment

- Improve drainage and reduce water damage risks

- Channel water into existing drainage underground

- Optional galvanized grates resist corrosion

- Aesthetically compliment newly poured or established driveway

How to Install a Driveway Drain Grate

Step 1: Prepare the d rain o pening .

Before installation, ensure your drain opening is clear of debris and pre-sloped properly as per industry standards to facilitate water flows. Inspect any existing drainage system to identify needed repairs in advance. Also, ensure you have the correct grate to fit your drain outlet. You will also need a sledgehammer, shovel, gravel, and protective gear , like work gloves.

Step 2: Choose a d rain g rate .

Select from grates compatible with your drain size and drainage needs. Most commercial properties will require grates that handle heavier loads and more wear, so plastic grates won’t likely be compatible with your project. Browse options at your big box or drainage supply store .

Step 3: Set the d rain g rate.

Lower the grate carefully into position over the opening. For projects that require pouring concrete , set grates before pouring to avoid surface water damage during curing. We discussed why this is so in our post on concrete vs asphalt parking lots . Also, established driveways require a trench or channel drain kit at minimum.

Step 4: Secure i t in p lace .

Most driveway drain grates feature a locking mechanism like bolt anchoring to ensure the grate is set firmly in concrete for stability. Pro series options even include weep holes for self-leveling stability. Ensure the grate is level and properly fitted before use.

Step 5: Adjust as n eeded .

Inspect periodically and re-level any settling grates using pea gravel packing under low spots. Replace worn or damaged grates as soon as possible to confirm your drainage system is in top working form.

Driveway drain grates provide durable protection for drainage systems.

In conclusion, driveway drain grates serve an important role in safeguarding drainage systems and preventing premature failure or flooding issues. While often a simple addition, installing the right grate for your specific drain and conditions can have major benefits for both landscape and infrastructure upkeep. By filtering debris from entering, grates keep drains clear and flowing efficiently.

Should you need any advice selecting high-quality grates or drainage products, our team of paving experts is here to help specify the optimal grate type and drainage design unique to your site conditions and traffic needs. Overall, driveway drain grates deliver simple yet effective protection to keep water moving freely through drainage systems year-round.

Here at TMC Engineering , we have a deep commitment to delivering projects executed using the highest standards for safety , workmanship, and client satisfaction. We aim to provide you with valuable content and insights related to the services our team of experts provides! Whether you require asphalt paving , striping, sealing , or concrete work , we offer a full suite of transportation construction solutions. Look no further—we’ve got all you need and more!